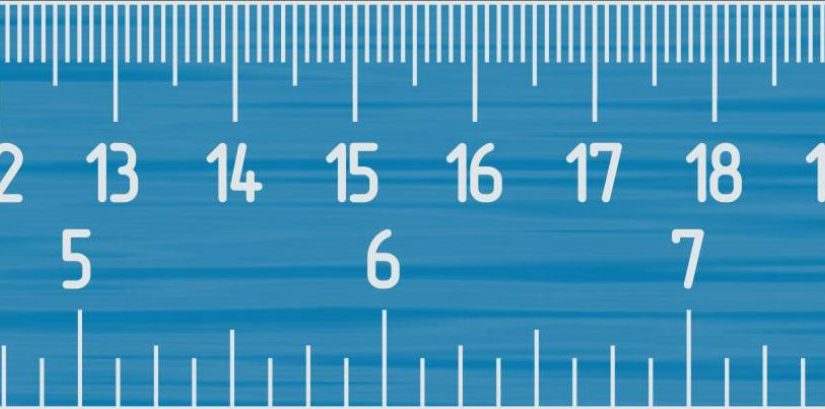

The shorter tapes are made with a curved, but rigid, cross section flexible enough to be rolled up. Steel tapes are made from 2m to about 10m in length. So that as soon as it is released it will automatically return to the case. The steel tape measure is an extendable steel strip coiled into a container. Steel tape (tape measure, push – pull steel tape, flexible ruler, retractable steel tape measure, flex tapes) The slide extends from the first strip of the ruler The slide can also be used as a depth gauge. The extension rule is a folding ruler which includes a brass slide for making internal measurements. The folding rulers cannot be relied on for extremely accurate measurements because a certain amount of play develops at the joints after continued use. The rule is usually made from strips, hinged in pairs to fold back on one another. Folding ruler is made from hardwood and reinforces at the ends with brass. It is the rule most often used by carpenters. It also overcomes the problem of carrying a long measuring rod to the workplace. The folding ruler can be used in a confined space where a long ruler would be inconvenient. Steel rulers may be flexible or non flexible, but the thinner the ruler, the easier it is to measure accurately because the division marks are closer to the work.įolding ruler (Zig – zag ruler, jointed ruler, surveyor’s rod) Steel rulers should be oiled to prevent rusting when not in use. The steel ruler is much more versatile and durable than wooden ruler. Its edges can be damaged through regular use affecting the accuracy of your measurementĪ steel ruler is essential for any kind of metal work and is also a useful tool in the woodwork workshop.The wooden ruler doaes have some disadvantages: The ruler itself is made from hardwood and is marked out in metric (millimetres) or imperial (inches) some rules have both. Wooden ruler is the woodworker’s traditional measuring instrument. Next image shows a piece divided into three equal parts. If it is desired to divide a piece into more than two parts lay the rule across the piece at such an angle as will bring two of its unit marks each upon an arris with the required number of divisions between. The middle of the piece will then be at that unit mark which is midway between these. Lay the ruler across the piece at an angle such that two of the unit marks shall rest each upon an arris. Next image illustrates a second method of finding middle of a piece. The middle of the piece being at a point midway between the marks selected. The ruler is used to find the middle of an edge by placing it across the piece so that the distances from the edges of the piece to corresponding fractional marks, shall be the same.

Whenever there are several measurements to be made along a straight line, the ruler should not be raised until all are made, for with each placing of the ruler errors are likely to occur. If the end of the ruler is inaccurate, start measuring at the 1cm mark. To measure and mark distances for accurate work, lay the ruler on edge so that the divisions on its side touch the stock. In making several small measurements do not move the ruler. Read the measurement from directly above the ruler. Keep the ruler at a right angle to the object. Put the ruler flat on object and read the measurement from the ruler. The ruler can also be used as a straight edge. Many rulers have a hole in one end so they can be hung up out of harm’s wayĪ 150mm (6 inch) and a 300mm (12 inch) ruler with both metric and imperial markings will cover most needs.

If the edges and ends are damaged, there will be inaccuracies. Rulers may be flexible or nonflexible, but the thinner the ruler, the easier it is to measure accurately because the division marks are closer to the work. The most common, and the best known, piece of measuring equipment is the ordinary ruler. A ruler, is an instrument used in geometry, technical drawing and engineering/building to measure distances and/or to ruler straight lines.Ĭonsiderable frustration and additional expense can be avoided by checking for a second time that the required measurement is accurately marked.

0 kommentar(er)

0 kommentar(er)